ABOUT US

We have been a supply partner of companies since 1962!

Image Box text

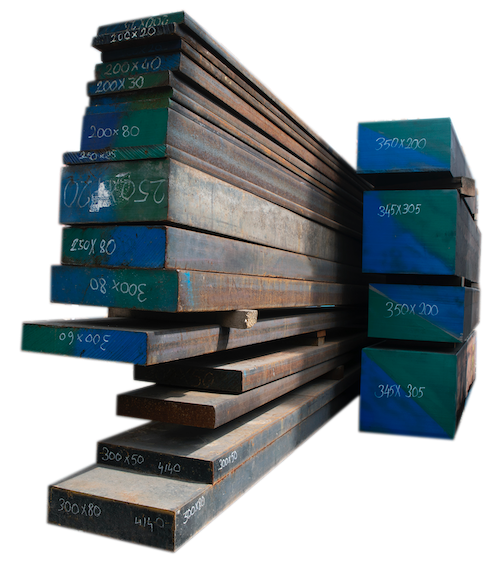

ALLOY STEELS

Carbon Steel is also known as machine steel due to its usage area. It is a type of unalloyed steel that includes all iron-carbon alloys with a carbon content between 0.35% and a maximum of 0.64% and contains only natural iron components such as sulphur, manganese and phosphorus in addition to iron.

Depending on the composition and concentration of the steel compounds, properties such as hardness and tensile strength can be increased or decreased. Carbon Steel are frequently used in the construction and machinery industry.

It is widely used in many industrial activities such as making shafts, bolts, axles, pins and gears in the machinery industry, transport (automobiles, trucks, wagons and marine construction), piping and boiler making for chemical industries, offshore construction, construction and mining etc.

| MKE Norm | DIN NO | TOOL NO. | SAE AISI | GENERAL AREAS OF USE |

|---|---|---|---|---|

| Ç 1040 | C 35 | 1.0503 | 1040 | Machine parts that do not require high strength, arrows, shafts, studs, etc. |

| Ç 1050 | C 45 | 1.0503 | 1050 | Piston pins, chain pins, gear shafts, worm gears, knurled rollers, camshafts, lift shafts, gear parts, automobile and engine parts |

| Ç 1060 | C 60 | 1.0601 | 1060 | Shafts, shafts, bolts, axles, gears, sprockets, sprockets |

| SAE/AISI | C | Mn | Si | P | S |

|---|---|---|---|---|---|

| 1040 | 0.35 - 0.44 | 0.60 - 0.90 | 0.10 - 0.30 | 0.040 max. | 0.050 max. |

| 1050 | 0.45 - 0.54 | 0.60 - 0.90 | 0.10 - 0.30 | 0.040 max. | 0.050 max. |

| 1060 | 0.55 - 0.64 | 0.60 - 0.90 | 0.10 - 0.30 | 0.040 max. | 0.050 max. |

| SAE/AISI | FORMING | SOFTENING | NORMALISED | HARDENING | TEMPERING |

|---|---|---|---|---|---|

| 1040 | 1100 - 850 °C | 650 - 700 °C | 860 - 890 °C | 850 - 870 °C Water - Oil | 550 - 660 °C |

| 1050 | 1100 - 850 °C | 650 - 700 °C | 840 - 870 °C | 820 - 860 °C Water - Oil | 530 - 670 °C |

| 1060 | 1050 - 850 °C | 650 - 700 °C | 820 - 850 °C | 815 - 830 °C Water - Oil | 550 - 600 °C |

| SAE/AISI | SOFT ANNEALING STATE | NORMALISED VERSION | IMPROVED VERSION | INDEX SURFACE HARDNESS |

|---|---|---|---|---|

| 1040 | Max. 172 HB | (180 HB) 60 kg/mm² | 65 - 80 kg/mm² (200 - 235 HB) | 50 HRC |

| 1050 | Max. 220 HB | (204 HB) 70 kg/mm² | 75 - 85 kg/mm² (220 - 260 HB) | 55 HRC |

| 1060 | Max. 241 HB | 80 kg/mm² | 80 - 95 kg/mm² | 60 - 65 HRC |